As the old saying goes, first impressions count. This attitude is especially crucial in the business sector, as labeling has a significant impact on an establishment’s bottom line. Wrong labeling is likely to result in a decrease in sales, robbing the firm of its full potential.

In general, a good label sticker provides all of the information that buyers value the most. This information might contain product data like components or recommended doses. Stickers are also utilized as distinctive branding tools to promote a product and increase its market visibility.

As a result, it is critical that you choose the appropriate sticker maker for your requirements. However, considering the variety of possibilities available in today’s market, you may find yourself in a difficult situation when selecting the best manufacturer for your specific needs. The following is a list of considerations to examine to ensure you make the proper decision.

Sticker Options:

To pick the best manufacturer, you must first grasp the fundamentals of the branding sector. This mostly provides information on how to purchase the stickers and the materials utilized in their creation.

Materials Used:

To get the most out of your purchase, pick stickers manufactured from high-quality materials, just as you would with any other finished product. Essentially, the higher the material quality, the greater the sticker’s aesthetic value and longevity.

Most sticker makers employ paper or PP (polypropylene) to make label stickers. The former entails adding a sticky component to the material’s backside, but the latter provides a more adaptable choice because it is a thermoplastic polymer. As predicted, polypropylene has greater durability and adhesive characteristics than paper. However, the paper may have changed, such as satin or gloss coatings, for improved performance.

Buying Your Stickers

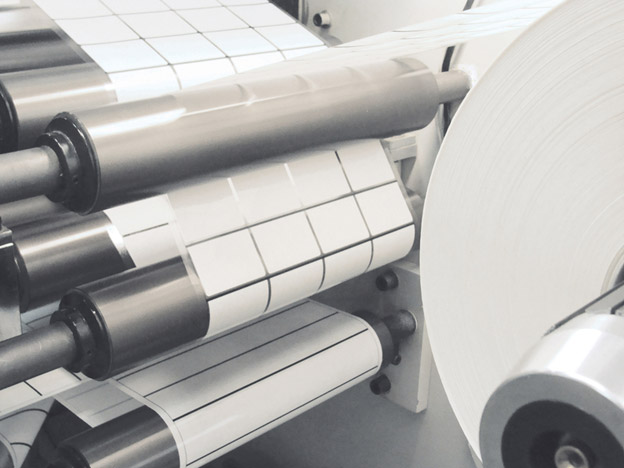

In addition to the material, decide how you want to receive your labels. There are three major options: continuous sheets, die-cut stickers, and stickers on a roll. Die-cut stickers are fashioned and sent individually, whereas continuous sheet stickers are printed on an A-size folio that includes pre-cut forms. Finally, label stickers on a roll are self-adhesive prints that come in a wrapped roll.

Factors to Consider When Selecting the Right Sticker Manufacturer

Choosing the proper sticker maker is all about the company’s experience and track record. You must consider various aspects.

Experience

Although it would be unjust to single out beginner sticker producers, it is reasonable to say that experienced manufacturers are more suited to meet your specific requirements. With numerous years of experience, such manufacturers can readily recognize difficulties before they develop and devise unique solutions to save you time and money. More significantly, they have the technological competence to produce in volume.

Budget

It is also critical to choose a sticker maker who is prepared to work within your budget. Ideally, it is critical to obtain high-quality stickers while maintaining your company’s profitability.

Turnaround Time

Delays in sticker manufacturing are bad for any firm. You will be compelled to delay the launch of your items, which will have a negative impact on your bottom line. Make careful you choose a company known for its short response times. Look for customer reviews and ask for references.

Finding the correct manufacturer is a key aspect of your business. ID Images LLC is one of the most widely regarded sticker producers and a fantastic spot to begin your search. We not only give you the products, but also all of the marketing know-how you need to grow your brand, making us the best sticker manufacturers for your needs.

Ice Making Machines for Outdoor Events in Australia: A Practical Guide

Ice Making Machines for Outdoor Events in Australia: A Practical Guide  Commercial Ice Makers for Non-Food Industries: Medical, Mining & More

Commercial Ice Makers for Non-Food Industries: Medical, Mining & More  Air Fryer vs Deep Fryer: Which Is Healthier?

Air Fryer vs Deep Fryer: Which Is Healthier?  Best Beer and Restaurant Experience in Bozeman

Best Beer and Restaurant Experience in Bozeman  WHERE CAN YOU GET SUPER FRESH SEAFOOD IN MIAMI?

WHERE CAN YOU GET SUPER FRESH SEAFOOD IN MIAMI?  Top Place in Bozeman for Flavorful Chicken and Montana-Made Beer

Top Place in Bozeman for Flavorful Chicken and Montana-Made Beer  Key Design Considerations for an Efficient Food Cold Room

Key Design Considerations for an Efficient Food Cold Room  A Thoughtful Guide to Wine Gifting for Mother’s Day and Beyond

A Thoughtful Guide to Wine Gifting for Mother’s Day and Beyond  How to Deep Fry Without a Deep Fryer Basket: Alternatives

How to Deep Fry Without a Deep Fryer Basket: Alternatives